1 Follower

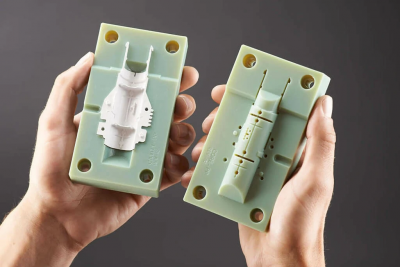

Overmolding is a process in which a material is molded over another material to create a single finished product. This technique has gained popularity in various industries due to the numerous benefits it offers, including improved durability, enhanced functionality, and aesthetic appeal. Overmolding allows manufacturers to combine different materials with unique properties to create products that are more reliable, stronger, and better performing.

When it comes to creating high-quality products that stand out in the market, having expert overmolding services is crucial. Overmolding is a process in multi-material manufacturing where a material is molded over another to create a cohesive and durable product. This process not only enhances the aesthetics of the product but also improves its performance and functionality.

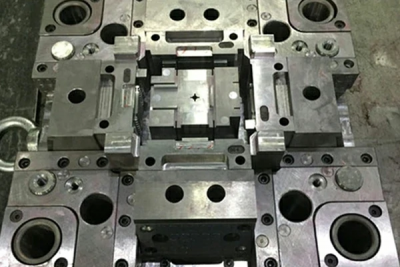

Custom injection mold tooling offers efficient solutions for specialized projects that require precision and accuracy. When it comes to complex manufacturing processes, having the right tools is essential to ensure the quality and consistency of the end product.

Custom injection mold tooling is a crucial aspect of the manufacturing process for companies with unique production needs. These tools are tailored specifically to the dimensions and specifications of the desired product, ensuring high precision and accuracy in the manufacturing process.

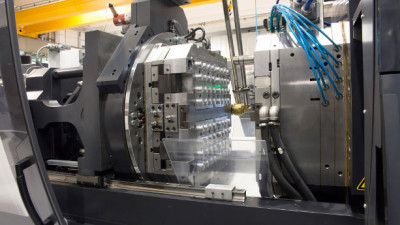

When it comes to plastic injection molding, Mexico is home to a number of top manufacturers that offer comprehensive services to meet various manufacturing needs. These companies are known for their expertise, experience, and state-of-the-art facilities that allow them to produce high-quality plastic parts efficiently and cost-effectively.

When it comes to manufacturing precision parts and components, advanced injection molding solutions in Mexico are leading the way in providing high-quality production services. With the latest technology and state-of-the-art equipment, companies in Mexico are able to offer comprehensive plastic injection molding services that meet the strictest quality standards.

When it comes to plastic injection molding, Mexico is home to a number of top manufacturers that offer comprehensive services to meet various manufacturing needs. These companies are known for their expertise, experience, and state-of-the-art facilities that allow them to produce high-quality plastic parts efficiently and cost-effectively.

Blush, also known as gate blush, is a common issue that can occur during the injection molding process. It is characterized by a hazy or cloudy appearance on the surface of the molded part near the gate area. This cosmetic defect can be a result of various factors, such as temperature, pressure, or gate design.

Gate blush in injection molding is a common issue that many manufacturers encounter during the production of molded parts. If you're unfamiliar with what gate blush is, let's break it down for you. Gate blush occurs when the plastic material in the gate area of a molded part shows signs of discoloration or frost-like marks. This can be a result of improper molding conditions or poor gate design.

Blush, also known as gate blush, is a common issue that can occur during the injection molding process. It is characterized by a hazy or cloudy appearance on the surface of the molded part near the gate area. This cosmetic defect can be a result of various factors, such as temperature, pressure, or gate design.

Are you looking to take your product manufacturing to the next level? Look no further than our reliable overmolding services. Overmolding is a process in which a substrate, typically made of plastic, metal or glass, is covered with a layer of molten material to create a durable and seamless finish. This process not only enhances the aesthetics of your product but also adds strength and longevity to its lifespan.

In the realm of manufacturing, tailored custom mold services are indispensable for companies aiming to achieve efficiency, quality, and innovation. From the initial concept to completion, these services provide a comprehensive approach to mold making that caters to the unique needs of each client.

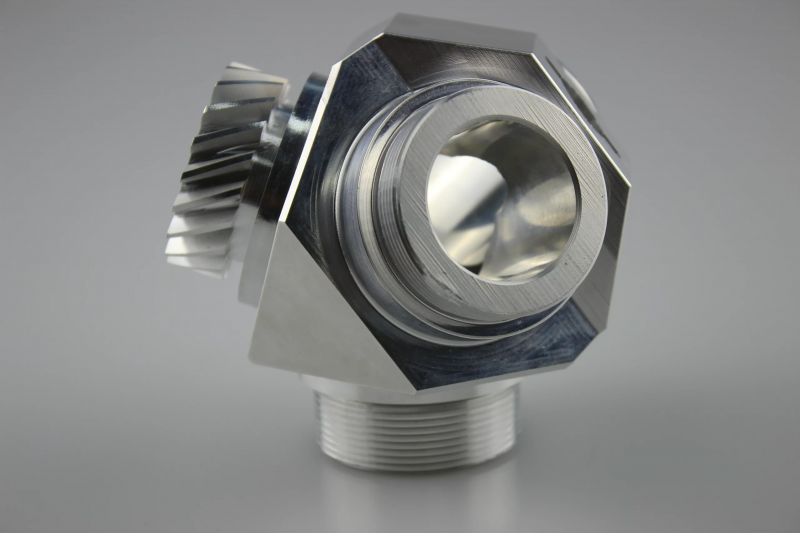

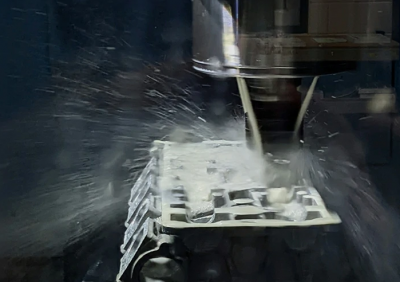

Prototype machining services play a crucial role in the product development process, enabling businesses and individuals to quickly turn their concepts into tangible prototypes. By utilizing advanced machining technologies and techniques, these services provide a rapid and cost-effective way to produce high-quality prototypes, allowing designers and engineers to test and refine their ideas before investing in large-scale production.

Prototype machining services are a crucial part of the product development process, enabling companies to quickly and accurately test and refine their designs. By creating a physical prototype, companies can validate their ideas, identify potential flaws, and make necessary improvements before moving into full-scale production. In this article, we will explore the benefits and applications of prototype machining services, and how they can help companies take their ideas from design to reality.

Prototype machining services play a vital role in the product development process, enabling inventors, entrepreneurs, and businesses to transform their innovative ideas into tangible, functional prototypes. These services utilize cutting-edge technologies and techniques to create precise, high-quality models that can be tested, refined, and eventually mass-produced. In this article, we will delve into the world of prototype machining services, exploring their significance, benefits.

Tapped holes are a fundamental concept in various industries, including manufacturing, engineering, and construction. A tapped hole is a hole that has been drilled and then threaded using a tap, allowing it to accept a screw or bolt. In this article, we will explore the basics of tapped holes and their advanced applications.

The die making process is a complex and precise process that involves creating a die, a specialized tool used to shape or cut materials into specific forms or designs. Dies are used in various industries, including automotive, aerospace, construction, and consumer goods, to produce parts with high precision and accuracy. In this article, we will provide a comprehensive overview of the die making process, highlighting the key stages involved in creating a die.

When it comes to custom aluminum extrusion, getting an accurate quote is crucial for ensuring that your project stays within budget and meets your specific requirements.

Bourque Industrial has established itself as the leading custom metal fabrication company in North Bay, ON, through years of dedication to craftsmanship, precision, and customer satisfaction.